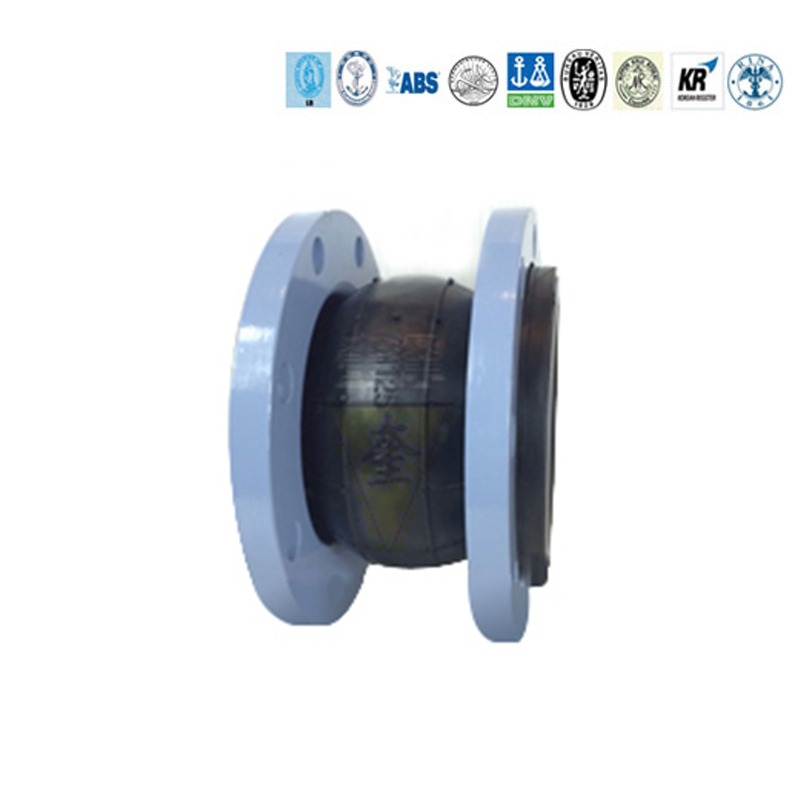

Product advantages of DN100 single ball rubber joint:

1. Reduce vibration, reduce noise, good flexibility, and easy to use.

2. Small size, light weight, good flexibility, easy installation and maintenance.

3.

It can produce lateral, axial and angular displacement during

installation, and is not restricted by the non-concentricity of the

pipeline and the non-parallel flanges.

4. It can reduce the noise transmitted by the structure while working, and has a strong ability to absorb vibration.

5.

Due to the good comprehensive performance of rubber joints, it is

widely used in basic engineering such as chemical industry,

construction, water supply, drainage, petroleum, light and heavy

industry, refrigeration, sanitation, plumbing, fire protection, electric

power, etc. It is especially suitable for large vibration and cold

Pipes with frequent thermal changes.

Product features of DN100 single ball rubber joint:

1.

KXT type DN100 single ball rubber joint has high internal density, can

withstand higher pressure, and has good elastic deformation effect. This

product is manufactured by the new process of air blowing molds. It is a

product composed of inner rubber layer, reinforcement layer, middle

rubber layer, outer rubber layer and composite ball and loose forged

low-carbon steel flange. It has high pressure resistance and good

elasticity. , Large displacement, good shock and noise reduction effect,

convenient installation and other characteristics. It can be widely

used in pipeline systems such as water supply and drainage, HVAC, fire

fighting, compressors, papermaking, pharmaceuticals, ships, water pumps,

fans, etc.

2. The rubber joint is composed of fabric-reinforced

rubber parts and loose metal flanges, which are used for pipe noise

reduction, shock absorption, and displacement compensation joints. It is

a pipe joint with high elasticity, high air tightness, medium

resistance and weather resistance. Strictly follow international

standards and raw material quality requirements to prevent cutting

corners. Environmental protection standards mean that product raw

materials require not only new materials, but also

environmentally-friendly new materials.

DN100 single ball rubber joint rubber ball material:

The

rubber soft joint sphere is composed of an inner rubber layer, a

reinforced layer with a multi-layer scraped nylon cord fabric, and an

outer rubber layer composite rubber tube. According to different media,

the rubber materials used are different, such as natural rubber, styrene

butadiene rubber, butyl rubber, nitrile rubber, EPDM, neoprene,

silicone rubber, fluorine rubber, and so on. Respectively have the

functions of heat resistance, acid resistance, alkali resistance,

corrosion resistance, abrasion resistance, and oil resistance.

Instructions for use of DN100 single ball rubber joint:

1.

When using this product for high-level water supply, the pipe must have

a fixed bracket, otherwise the product should be installed with

anti-pull support device. The force of the fixed support or bracket must

be greater than the axial force, otherwise the anti-pull support device

should also be installed.

2. You can choose to use the working

pressure according to your own pipeline: 0.25mpa, 1.0Mpa, 1.6Mpa,

2.5Mpa, 4.0Mpa flexible rubber joints, and the connection dimensions

refer to the "Flange Size Table".

Material of each part of DN100 single ball rubber joint:

1.

Inner rubber: NR, NBR, EPDM (you can choose high temperature

resistance, acid and alkali resistance, oil resistance, abrasion

resistance, etc.)

2. Outer layer glue: NR, NBR, EPDM (you can

choose high temperature resistance, acid and alkali resistance, oil

resistance, abrasion resistance, etc.)

3. Main frame: nylon cord (the same material as the tire inside)

4. Pressurized ring: high-pressure steel wire rope

5.

Flange: carbon steel Q235A (forged) surface sprayed with anti-rust

paint, stainless steel 301, stainless steel 316L, PVC material)

DN100 single ball rubber joint chooses different rubbers to play different roles:

1. Natural rubber NR (over water, below 80 degrees)

2.

EPDM (high temperature below 150 degrees, acid and alkali resistance,

corrosion resistance, power plant desulfurization, lime slurry, gas,

etc.)

3. Nitrile rubber NBR (oil resistance, including hydraulic

oil, aviation kerosene and other oils, high temperature resistance below

150 degrees)

4. Wear-resistant rubber TZ (wear-resistant, generally used in the mineral industry, granular medium conveying pipelines)

5. Special rubber (emulsion, sulfuric acid and other special media)

Introduction of rubber joints:

Rubber

joints are shock-absorbing joints installed at the inlet and outlet of

the water pump, which can effectively ensure the service life of the

water pump, and can also absorb the noise and vibration generated by the

water pump when it is working. It can be installed on various vibration

pipes, and the central air-conditioning host Imported and exported,

etc., the service life is up to 5 years, the service life of special

materials is 3 years, and the use cost is low. It is the first product

for sound insulation and noise reduction in many pump rooms.

Installation of rubber joints:

1.

Please use the following standards (special flange for wafer type

butterfly valve) when selecting pipeline flat welding flange. The

sealing surface of rubber joint and the sealing surface of soft sealing

butterfly valve need to be sealed with special flange for butterfly

valve to achieve the best sealing effect.

2. The inner diameter

of the connecting part of the water pipe mouth must be the same as the

inner diameter of the rubber shockproof joint.

3. The flange

contact surface of the flange connected to the water pipe port must be

smooth and flat in order to ensure a large sealing space. (As shown in

the figure below), when the rubber anti-vibration joint is not tightly

connected with the contact surface of the water pipe mouth, noise,

insufficient pressure, and water leakage will occur.

DN100 single ball rubber joint remarks requirements:

1.

Special requirements can be made according to user drawings, flange

standard adopts GB/T9115.1-2000, optional (GB, JB, HG, CB, ANSI, DIN,

BSEN, NF, EN, JIS, ISO, etc.) method Blue standard production. The

rubber ball can be made of natural rubber, EPDM rubber, neoprene rubber,

butyl rubber, nitrile rubber, fluorine rubber, etc.

2. When

products above DN200 are used for suspended water supply, the pipeline

must have a fixed support or a fixed bracket, otherwise the product

should be equipped with an anti-pull device.

3. If the user uses

rubber joints, the corresponding flange should be a valve flange or a

flange that conforms to GB/T9115.1-2000.